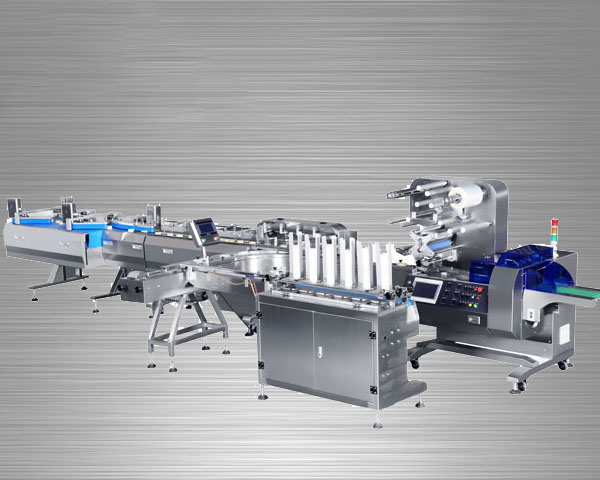

Machine Specifications:

|

Packaging Speed |

5-120 bag/min.per line |

|

Bag Length |

Min.120mm |

|

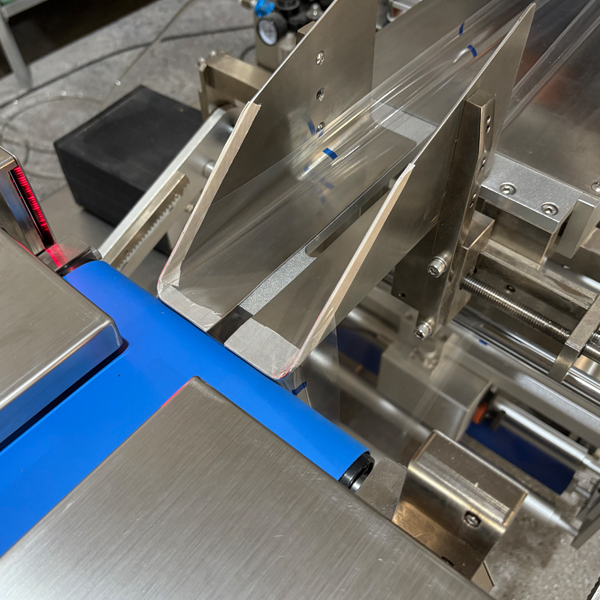

Bag Width |

80-200 mm |

|

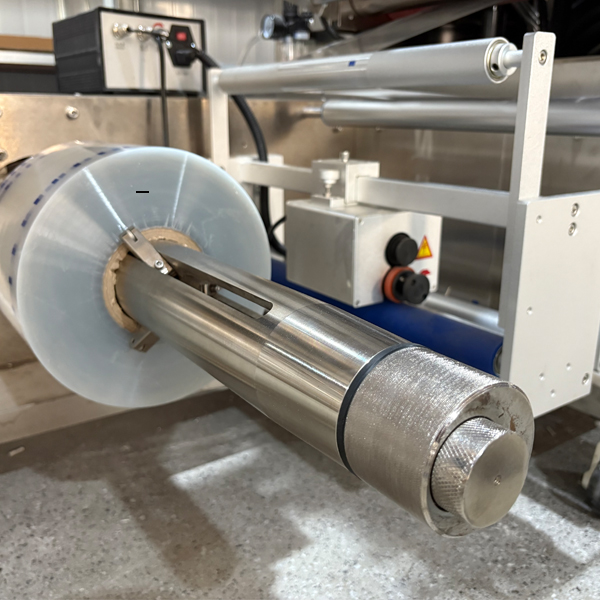

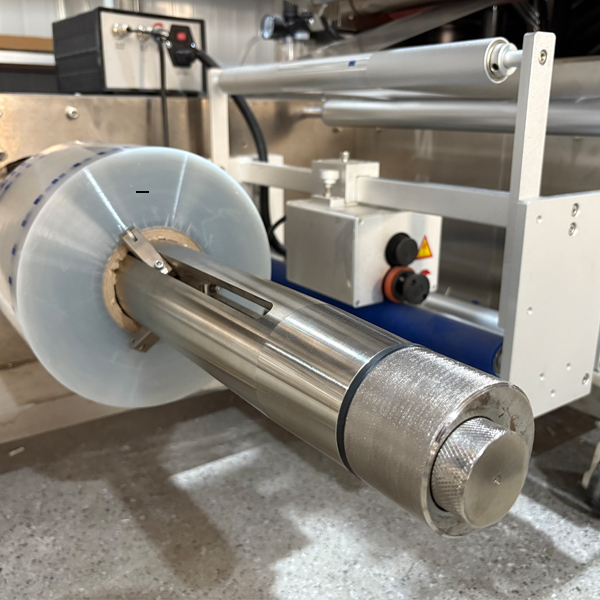

Film Width |

Max. 450mm |

|

Product Height |

1-150mm |

|

Film Roll Diameter |

Max. 320mm |

|

Packaging Material |

Paper, Plastic, OPP, PVC, PT/PE, OPP/CPP |

|

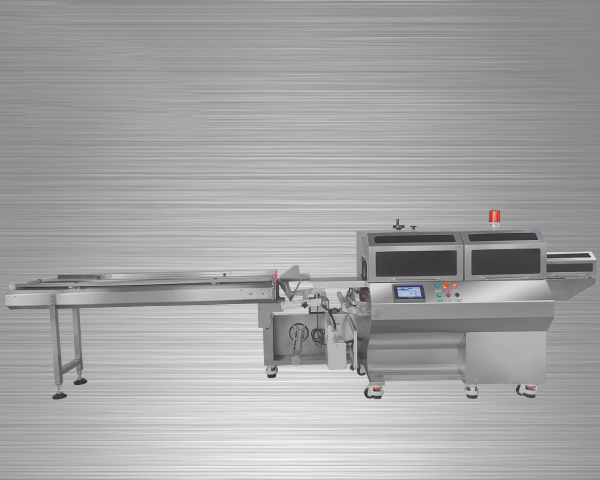

Machine Dimension(LWH) |

423510301255 mm |

|

Power Supply |

220V, 50/60Hz,5.6KVA |

|

Machine Weight |

About 1120kg |

Electrical Configuration:

|

PLC |

Panasonic from Japan |

|

Servo motors |

Panasonic from Japan |

|

Servo drivers |

Omron from Japan |

|

Switch Button |

Schneider from German |

|

Terminals |

Wade Miller from German |

|

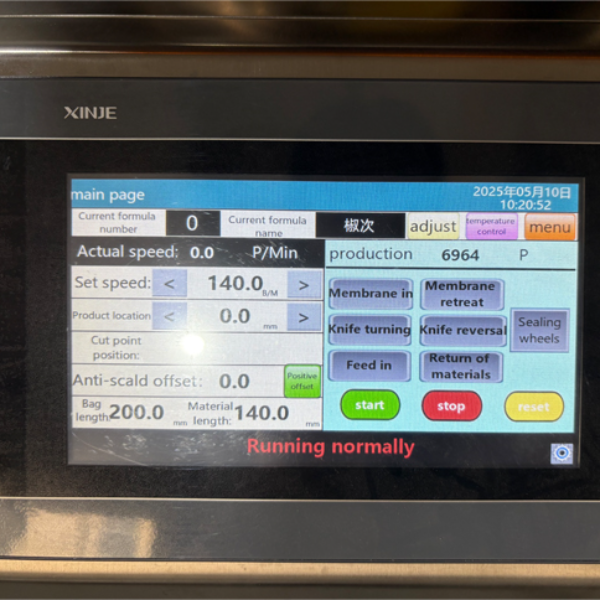

Display Screen |

XINJE from China |

|

Cylinder |

AirTAC from Traiwan |

|

Photocell |

SICE from German |

|

Temperature Control List |

Omron from Japan |

|

Pushbutton Switch |

Schneider from German |

|

Power |

Ming Wei from Taiwan |

|

Intermediate Relay |

Omron from Japan |

|

Two Wire Switch |

Schneider from German |